Today, many industries are struggling with complex operations, high energy bills, old equipment, and strict rules. Traditional control systems just aren’t enough anymore. To keep up, companies need smarter tools that help them see what’s happening, solve problems early, and run things better in real time.

That’s where Digital Twin technology comes in. It creates a virtual copy of real-world systems, helping businesses understand and improve how things work using live data.

At CIMCON, we’re making this technology accessible by offering powerful, AI-based Digital Twin solutions. From factories and utilities to energy systems and smart cities, our solutions are already helping organizations boost efficiency, reduce downtime, and make smarter decisions.

What is a Digital Twin?

A Digital Twin is a real-time virtual representation of a physical asset, process, or system. It continuously receives input from sensors, controllers (PLCs, DCS), SCADA, historians, and databases to replicate current conditions, simulate future scenarios, and deliver predictive insights.

Unlike one-time simulations, a Digital Twin keeps evolving with the physical asset it grows and changes as the real system does. It becomes a reliable source of truth for engineers, operators, and decision-makers.

By integrating operational technology (OT) with information technology (IT), Digital Twins provide a unified view of asset health, performance, and operational efficiency—transforming raw data into actionable intelligence.

Why Digital Twin? The Growing Need Across Industries

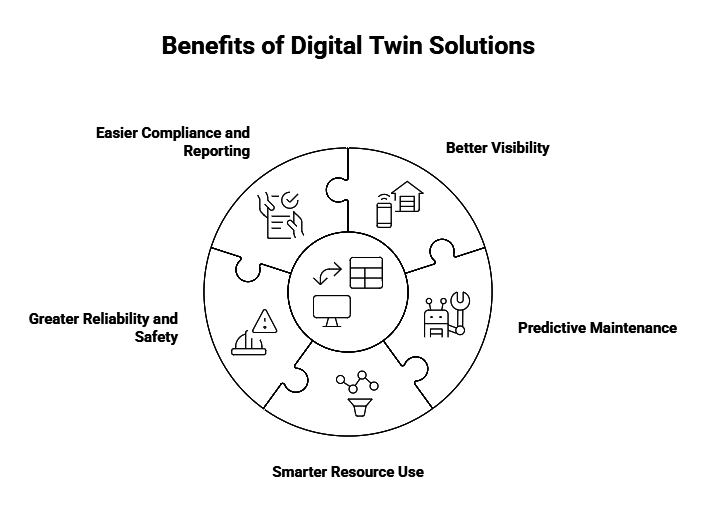

From utilities and manufacturing to smart cities and oil & gas, organizations everywhere are turning to Digital Twin solutions. As systems become more complex and expectations rise, Digital Twins help businesses stay ahead by offering:

- Better Visibility

Monitor all your assets in one place, even if they’re spread across different locations. Get real-time data and key performance indicators (KPIs) at your fingertips. - Predictive Maintenance

Use machine learning to catch early warning signs before issues become costly breakdowns. This helps reduce downtime and extends the life of your equipment. - Smarter Resource Use

Continuously improve operations to save energy, minimize material waste, and cut operational costs all without compromising performance. - Greater Reliability and Safety

Spot faults or unusual behavior early, so you can act before small issues turn into major failures or safety risks. - Easier Compliance and Reporting

Automatically generate reports and records that are audit-ready and meet regulatory standards—saving time and reducing manual errors.

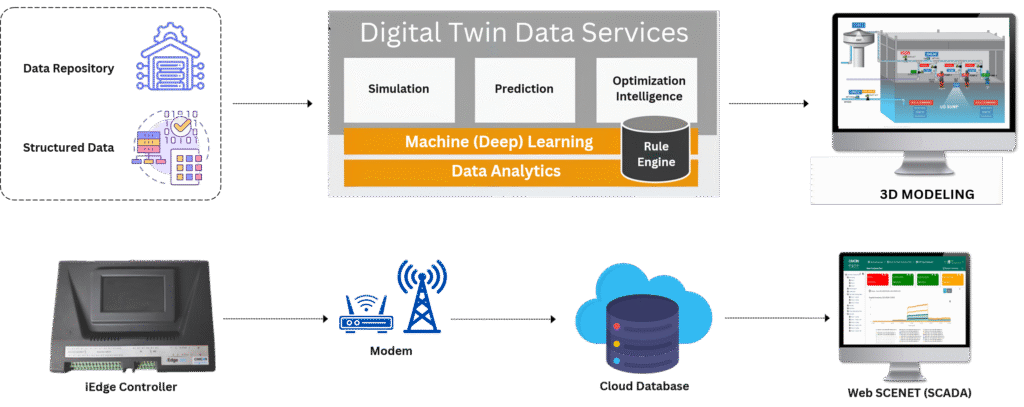

Central Command and Control Architecture

Digital Twin solutions are modular, scalable, and built to meet cross-industry needs. The architecture integrates edge, cloud, analytics, and visualization layers to create a closed-loop operational intelligence framework.

Data Acquisition & Integration

- Connects to field devices (sensors, meters, RTUs), PLCs, SCADA systems, and enterprise data sources.

- Supports industry-standard protocols like OPC-UA, Modbus, MQTT, and REST APIs.

- Ingests telemetry data from rotating equipment, pipelines, energy systems, and utilities infrastructure.

Edge and Cloud Analytics

- Performs near-real-time processing at the edge for time-sensitive applications.

- Supports historical data analysis, event detection, and process optimization.

- Enables hybrid deployments (on-premise, private cloud, or public cloud) for flexibility and security.

AI and Simulation Engine

- AI/ML models for anomaly detection, condition monitoring, fault prediction, and optimization.

- Virtual simulation of control strategies, energy profiles, process workflows, and failure modes.

- Supports multi-scenario comparison and decision validation.

Visualization & Dashboards

- Interactive dashboards tailored for maintenance, operations, and executive teams.

- Visual asset modeling, real-time KPIs, historical trend analysis, and alert systems.

Accessible via web, mobile, and control room interfaces.

Utilities: Water, Wastewater, and District Cooling

Water and energy utilities often deal with aging infrastructure, hidden leakages, and rising energy costs especially in large, spread-out networks. Digital Twin technology helps tackle these challenges by offering centralized visibility, predictive insights, and smarter control.

Key Use Cases:

- Non-Revenue Water (NRW) Management: Spot leaks early by analyzing unexpected pressure drops or inconsistencies in flow helping reduce water loss and improve supply efficiency.

- Pump Station Optimization: Apply AI-driven recommendations to adjust pump speeds and frequencies, cutting down energy usage without compromising performance.

- Water Demand Forecasting: Predict demand patterns by season or time of day, enabling better reservoir management and supply planning.

- Remote Treatment Plant Monitoring: Get a real-time view of plant operations—including turbidity, chlorine levels, flow rates, and chemical dosing—from a centralized dashboard, accessible anytime, anywhere.

Oil & Gas and Energy Infrastructure

In the oil & gas and broader energy sector, systems like pipelines, storage tanks, and processing plants must operate with maximum safety, reliability, and uptime. Digital Twins help achieve this by creating real-time, intelligent models of critical infrastructure enabling smarter operations, early risk detection, and energy optimization.

Key Use Cases:

- Pipeline Leak & Corrosion Detection

Monitor flow rates, pressure drops, and cathodic protection systems to catch leaks or corrosion early reducing environmental and operational risks. - Compressor & Turbine Health Monitoring

Analyze vibration and thermal patterns to predict failures and schedule maintenance before breakdowns occur. - Tank Farm Automation

Enable real-time tracking of tank levels, automate valve sequences, and simulate emergency shutoff scenarios for better safety and control. - Energy Management in Refineries

Use load-based analytics to optimize energy consumption across blowers, heat exchangers, and motors improving efficiency and lowering costs.

Smart Buildings & Commercial Complexes

Commercial campuses and buildings are embracing Digital Twin technology to make operations smarter, reduce energy and maintenance costs, and create more comfortable experiences for occupants.

Key Use Cases:

- HVAC Optimization

Dynamically adjust air handling units and chillers based on occupancy, CO₂ levels, and outdoor conditions to balance comfort and efficiency. - Energy Benchmarking

Compare real-time energy usage against ideal baselines across zones and systems to identify savings opportunities. - Predictive Maintenance

Anticipate failures in elevators, pumps, or fire systems before they disrupt operations. - Asset Lifecycle Management

Monitor usage patterns of lighting systems, sensors, and backup generators to optimize replacements and extend asset life.

Smart Cities & Urban Infrastructure

Modern cities require a connected, real-time view of their critical infrastructure—from utilities to mobility. A city-wide Digital Twin serves as a virtual control center, enabling proactive governance and efficient urban management.

Key Use Cases:

- Integrated Utility Monitoring

Track and manage water, sewage, gas, and electricity distribution across various city zones. - Traffic & Lighting Optimization

Simulate traffic signal changes and public lighting adjustments to improve flow and reduce energy use. - Environmental Compliance

Monitor air quality, noise, and emissions to stay within regulatory limits and improve citizen health. - Disaster Preparedness Simulation

Model emergency scenarios such as floods or blackouts to test and strengthen city response plans.

Infrastructure & Construction

For large-scale infrastructure and capital projects, Digital Twins provide visibility not just during construction, but throughout the entire asset lifecycle from build to operations.

Key Use Cases:

- Construction Progress Tracking

Link digital models to site layouts, delivery milestones, and material usage to monitor progress in real time. - Asset Commissioning Validation

Digitally verify equipment installation, calibration, and commissioning against design specs before handover. - Post-Handover Maintenance

Continue monitoring installed assets for warranty tracking and early fault detection. - Digital Handover Documentation

Maintain accurate “as-built” records, including real-time asset condition histories for future operations and audits.

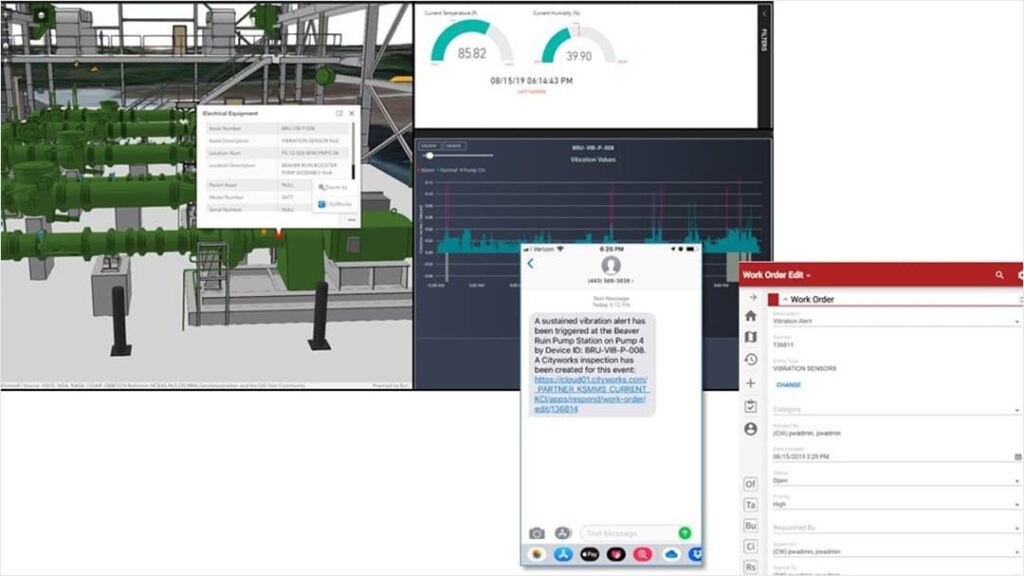

JWIL Success Story – A Scalable Digital Twin in Action

Problem Statement

JWIL, a leading water utility operator, faced multiple operational challenges in managing its geographically dispersed water generation and pumping infrastructure.

Key issues included:

- Limited Operational Visibility: Existing monitoring was siloed and lacked real-time integration across assets.

- High Energy Consumption: Pump operations were not optimized for varying demand and system conditions, leading to significant energy inefficiencies.

- Reactive Maintenance: Mechanical faults such as bearing wear and cavitation were detected late, causing unplanned downtime and increased O&M costs.

- Non-Revenue Water (NRW) Losses: Undetected leakages and distribution imbalances impacted water availability and revenue recovery.

Solution Provided

CIMCON partnered with JWIL to design and deploy a robust, AI-powered Digital Twin for their water generation plants, pumping stations, and distribution networks. The solution integrated multiple data sources into a unified, intelligent operational framework.

Key Solution Highlights:

- Seamless Data Integration: Connected real-time pressure, flow, level, and energy telemetry from existing SCADA systems into a centralized monitoring dashboard.

- AI-Driven Performance Analytics: Deployed machine learning models to correlate pump energy usage with head pressure, identifying inefficiencies and optimization opportunities.

- Predictive Maintenance Capabilities: Used vibration data and historical trend analysis to detect early signs of mechanical faults such as bearing issues and cavitation.

- Mobile-First Operations: Provided field teams with on-the-go access to live alerts, KPI dashboards, and performance reports via mobile devices.

- Water Distribution Optimization: Applied demand forecasting and leak detection algorithms to support equitable water supply and NRW reduction.

Digital Twin For Pump House

Impact Achieved

The deployment delivered measurable operational, financial, and sustainability benefits for JWIL:

- 18% Reduction in Energy Consumption through optimized pump scheduling and setpoint adjustments.

- Improved Asset Lifecycle Planning with data-driven maintenance scheduling and fault prevention.

- Faster Fault Detection enabling proactive interventions before equipment failure.

- Enhanced Operational Efficiency with real-time visibility and mobile-enabled workforce responsiveness.

- Progress Toward NRW Reduction Goals through better leak detection and demand balancing.

CIMCON’s Digital Twin Roadmap

A Phased Journey Toward Intelligent Operations

CIMCON follows a structured, step-by-step approach to implementing Digital Twin solutions allowing organizations to progressively unlock value, regardless of their current system maturity.

Stage | Capability | Outcome |

Visual Twin | Real-time visualization of asset health and layout | Enhances operator awareness and situational understanding |

Connected Twin | Live integration with sensors, SCADA, and control systems | Enables real-time alerts, diagnostics, and performance tracking |

Predictive Twin | AI-driven analytics to forecast failures and resource needs | Minimizes downtime and improves operational planning |

Prescriptive Twin | Recommends best actions based on system behavior | Boosts efficiency, consistency, and decision-making |

Autonomous Twin | Self-learning and adaptive models for automation | Supports full closed-loop optimization and autonomous control |

This step-by-step framework ensures easy adoption and scalable deployment across legacy and modern systems alike.

Proven Business Impact with CIMCON’s Digital Twin

CIMCON’s Digital Twin deployments are delivering measurable results across industries—enabling organizations to transition from reactive operations to intelligent, data-driven decision-making.

- Significant reduction in energy costs through AI-driven process optimization.

- Noticeable decrease in unplanned downtime enabled by early fault detection and predictive maintenance.

- Faster, more informed decision-making by combining real-time insights with historical performance trends.

- Lower maintenance costs through precise fault isolation and root-cause diagnostics.

- Simplified compliance with automated data logging and audit-ready reporting.

Core Capabilities of CIMCON’s Digital Twin Platform

- Unified Real-Time Monitoring

Centralized dashboard for assets, KPIs, alerts, and anomalies giving teams complete operational visibility at a glance. - Predictive Diagnostics & Insights

Early detection of system drift, wear patterns, or potential failures using AI and advanced analytics. - Simulation & Control Optimization

Virtually model processes, optimize setpoints, and test operational scenarios—before applying changes in the real world. - Scalable, Future-Ready Architecture

Modular, microservices-based design easily deployable on-premises or in the cloud to fit your IT strategy. - Enterprise-Grade Security

End-to-end protection with secure APIs, encrypted communications, and role-based access control.

The Future of Operational Excellence

Digital Twin technology represents more than just a digital mirror it is a strategic asset for industries seeking agility, resilience, and sustainability.

Whether you’re managing a factory, utility, pipeline, commercial building, or smart city, the ability to see, simulate, and optimize operations in real time is a competitive advantage.

CIMCON’s Digital Twin solutions are already delivering this future today.

Ready to Start Your Digital Twin Journey?

Connect with our experts to learn how CIMCON can help you implement a tailored Digital Twin strategy that aligns with your business goals.

📍 Visit: www.cimconautomation.com

📧 Email: sales@cimconautomation.com

📞 Call: +91 72270 15902