SRP Automation

Owing to the mechanical nature of Sucker Rod Pumps, they are prone to failures. CIMCON’s innovative technology and solutions offer constant supervision and ensures continuous operation.

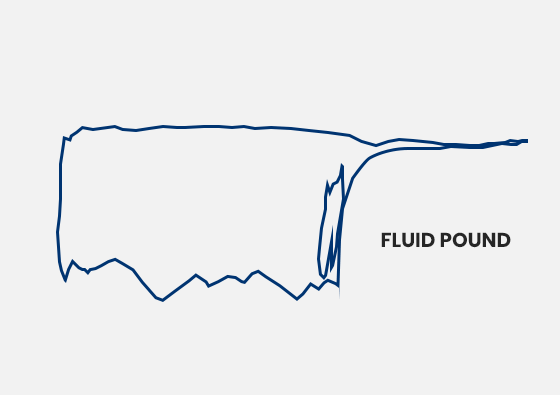

Matching the oil inflow with pump displacement through iRTU

CIMCON’s iRTU adjusts the pump off time to acquire sufficient fluid level to avoid fluid pounding. The pump-off time can be set or modified from remote location.CIMCON solution provides automatic start and Stop of pump on liquid level using Artificial Intelligence algorithms (without any sensor for liquid measurement).

Monitoring & controlling the downhole characteristics through Dynacard

From real-time surface to downhole dynamometer plots, daily gauging to fault and event logging, users can monitor multiple fields simultaneously from virtually anywhere in the world.

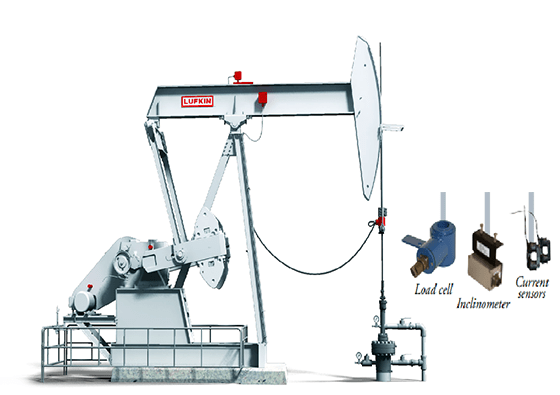

Configure I/O points through iRTU

The iRTU accepts feedback from a load cell, inclinometer, and current sensors to measure rod load, rod position, and motor torque apart from other sensor parameters. Wireless, radio, cellular, and satellite options allow remote telemetry.

- Monitors time-stamped well data, faults from RTU

- Acquire, compute stroke counts/ pump volume and pump up time

- Remote configuration of RTU parameters

- Display of well data locally

- Provision for manual data acquisition through designated port

- Pump fill monitor and Pump Off Control (POC)

- Monitors well intake, discharge pressure, flow & production

- Downhole pump, tubing, casing, fluid and reservoir models

- Monitor power consumption, efficiency calculation and report

- Monitors fluid level, downhole pump position, velocity, load and rod position

- Actual surface and pump dynamometer graph

- Predicted surface and pump dynamometer graph generators

- User-programmable MS Excel spreadsheet report generator software

- SCADA communication via wired/ wireless communication network

Money

Reduction of operating cost

Improved production accounting

Security

Improved safety due to the facility of remote operation

Environment

Better system efficiency due to availability of pump run data

Foundation

Improved data integrity through trend analysis

Early detection of problem to avoid expensive repairs

Extend pump life

Alert the operator with alarm messages

Increases manpower availability for analysis