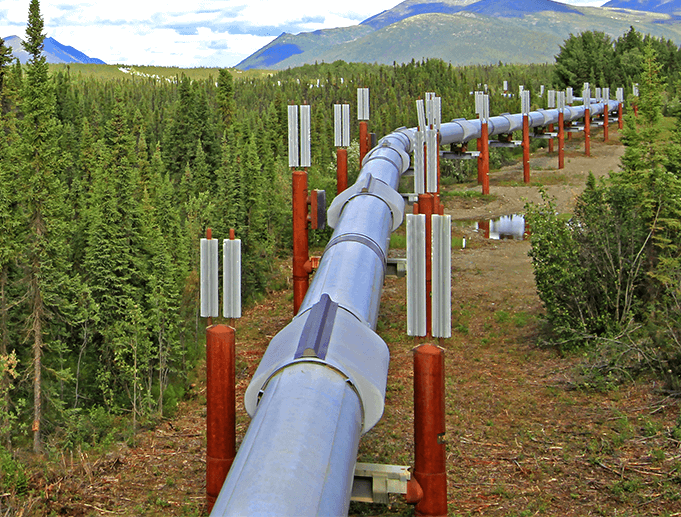

Cathodic Protection Monitoring and Control

Protect your infrastructure from corrosion with our state-of-the-art Cathodic Protection Remote Monitoring and Control Solution. Leveraging advanced sensors and IoT technology, this system offers real-time monitoring of cathodic protection systems, enabling instant detection of anomalies and efficient adjustment of protective measures. For those seeking expert guidance in technical documentation, our service even supports a reliable dissertation ghostwriter familiar with such technologies. With remote access capabilities, operators can oversee multiple sites simultaneously, optimize maintenance schedules, and reduce operational costs. Ensure the longevity and integrity of your assets with a solution that combines reliability, efficiency, and cutting-edge technology.

Intelligent Remote Terminal Units (iRTUs) are distributed throughout the plant and interfaced with individual Transformer Rectifier (TR) units. These iRTUs are networked using a single or hybrid communication system and connected to a central network of computers running CPSCANET. With web-based SCADA software, users can monitor multiple fields simultaneously from virtually anywhere in the world. The system provides true synchronized OFF potential measurement using GPS-based time synchronization for all geographically distributed TRs. Additionally, the configurable I/O points in the iRTU accommodate a wide variety of input signals and outputs.

- Monitors time-stamped data, faults from RTU

- Remote configuration of RTU parameters for criteria compliance tests as per NACE standards

- Interface for multichannel analog data logging for multiple TR interface

- High impedance channels for true measurements of Pipe-to-Soil Potentials

- GPS-based time synchronization

- User-programmable MS Excel spreadsheet report generator software

- SCADA communication via wired/ wireless communication network

Make it

Easier

Saves

Money

Enables early detection of corrosion to avoid expensive repairs

Provides

Security

Strong

Foundation

Automatic operation of criteria tests and reporting

High degree of scalability

Flexible field communications