Oil and Gas Pipe Line Monitoring System

Industrial Solution Deep Dive:

As a part of this section, we will be looking at tracking Oil and Gas pipe line monitoring system leveraging AI and IoT giving both Industrial Solution Deep Dive as well as detailing about the Application stack leverages. The section would include the following:

Industrial Solution Deep Dive

- Current Challenges

- Solution & Tech Components

- Lean Architecture & features

Current Challenges – Overview

O&G Pipe lines are laid underground or above ground in kms of length. The pipe line carries costly and hazardous fuels with high pressure. Small cracks, corrosion causes leakage in the pipe line which may incur loss to the Company and at the same time may have huge loss on environment / human hazards.

As a part of Integrity management of these pipelines, the foot patrolling of ROU (Right of use) of the pipeline needs to be monitored to avoid any Third party activity resulting into leak or fire.

The ROU monitoring activity is set on the basis of class location(population zones) through which pipe line is passing.

Based on the current scenarios, O&G companies are making physical survey of the system at the Test Lead Points for pipeline corrosion monitoring installed @ 1-1.5 km distance near Pipe line path and Right of Use (ROU) for physical condition monitoring of pipeline.

Manual survey are being carried out at different time interval monthly or bi-monthly on 200 to 400 km of distance and report are to be fed into the existing software by surveyor.

The foot patrolling will be on Daily & Monthly basis as required.

Typical areas where the monitoring has been done manually and cause the chances of errors:

- Line Patrol Man (LPM) should observe soil/ground surface condition on and adjacent to Pipeline /ROU (right of Use) area, indication of leak/construction activity other than company, encroachment and any other factors/activities affecting the safety and security of pipeline like Digging/Drilling/Boring/HDD etc. Patrolman will have to pay special attention to all Railway / Bridge / Road / River / Canal/Nala crossings.

- If any serious observation / abnormality is found which may be required to be reported immediately, along with photograph & location details.

- Any de-coloration of vegetation on the ROU is to be reported to investigate possible leak Each LPM shall keep their GPS tracking device always in charged and ON condition to monitor via GPS tracking portal.

- Deep rooted trees which are considered threat to the pipeline shall be reported to Local Control Room along with detailed information including photograph

- All vulnerable locations viz. river crossings, all cased Road / Railway / canal crossings, Encroachments, Excavation, Exposure, washout shall be checked with special care and to be reported with photograph

- Reporting on all activities being carried out on the ROU like, excavation, digging, construction, encroachment, exposure, wash out, plantation, leak, soil erosion etc.

Current Challenges – #1

Lack of Technology Awareness & Adoption

- Lack of Technology Awareness related to Artificial Intelligence & Related Technologies

- Lack of success stories in the adoption rate and churn curve

- Accuracy in Prediction Models for specific Tasks

- Joint Development considering customer pain point and need

Solutions and Tech Components

Use of technology in the infrastructure

- GPS co-ordinates at TLP locations and critical areas

- Web based software Plotting all GPS co-ordinates

- Artificial Intelligence based Virtual Drone image analytics

- AI help to identify old photos and compare new Google images for Encroachment, Tree and vegetation near ROU

- TLP unit to monitor Reference cell potential to identify pipes are protected from corrosion.

- TLP can monitor any Tilt (damage) to installed Unit

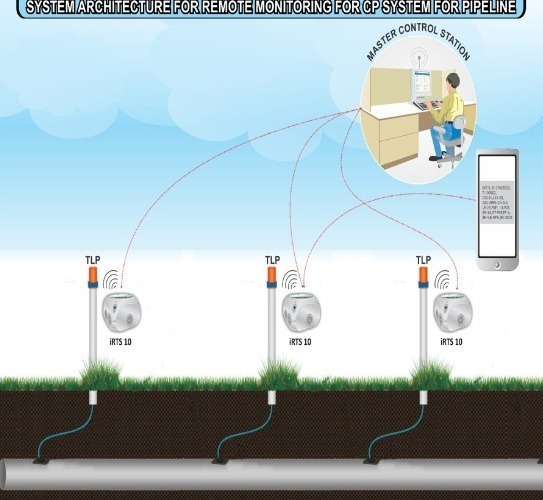

Lean Architecture and Features: TLP Monitoring System

- GSM based remote monitoring system

- Consists of a high accuracy, compact, Battery Powered Unit with built‐in GSM Modem

- Interface for continuous remote monitoring of Reference potentials, AC interference voltage and pipe Current at CP test stations

- High Input impedance channel for Ref. cell monitoring

- Device tampering Alert message to user

- Sleep-mode for long battery life

- Data logging via. Local interface i.e. RS-485/USB

- Remote communication to Web server

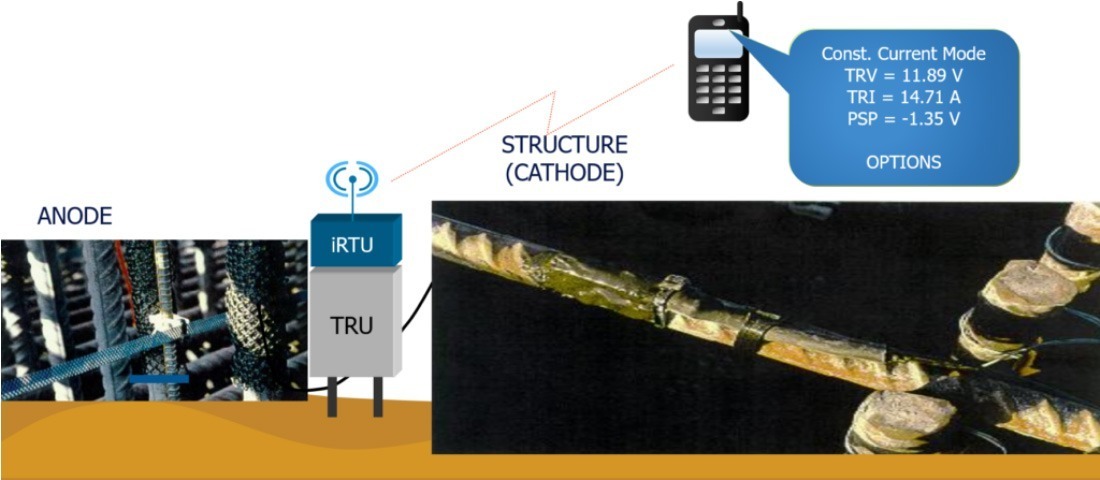

GSM Based Cathodic Protection Monitoring:

Get your TR Status, Mode of Operation, Real Time Voltage, Current and PSP on your mobile Handset.