ICCC- Water Management System (Smart City)

Industrial Solution Deep Dive

As a part of this section, we will be looking at monitoring Pump house and its efficiency, prediction of faults (pre alarm conditions), KPI (Power Vs Water distribution) and demand analysis, leveraging AI and IoT giving both Industrial Solution Deep Dive as well as detailing about the Application stack leverages. The section would include the following:

Industrial Solution Deep Dive

- Current Challenges

- Solution & Tech Components

- Lean Architecture & features

Current Challenges – Overview

- Water distribution pump houses are equipped with Pump, motor, starter panels, valves etc. basic infrastructure.

- Electro mechanical parameters plays important role for citizen water distribution system. i.e. Water Flow, pressure, Energy Measurement, Level etc,

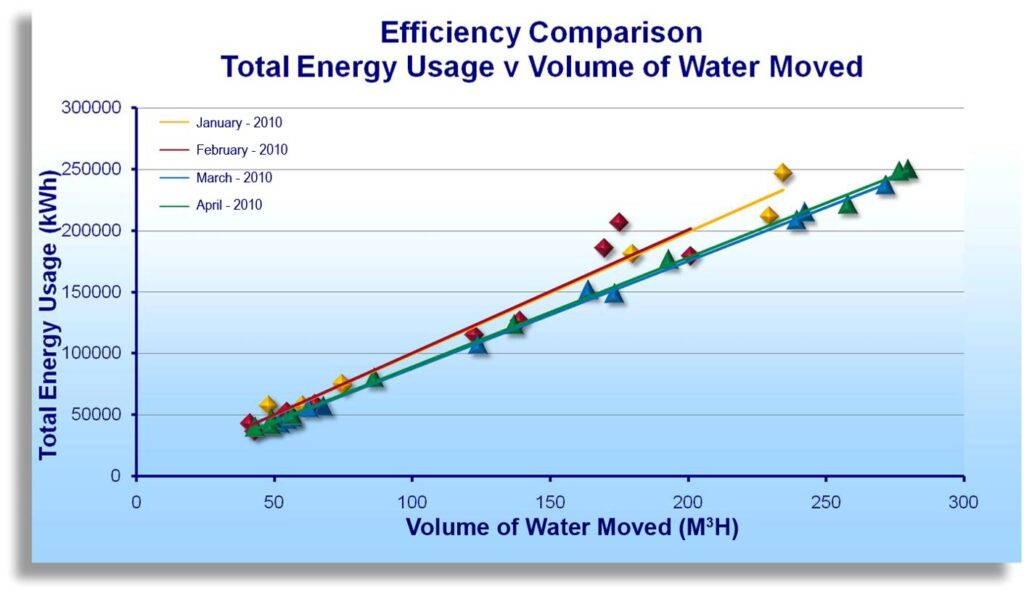

- Municipal officials are concerned about KPI (Key Performance Indicator) of Total Flow during the day (MLD) Vs Energy Use to distribute the water. (KWH / KL). The above KPI will decide overall efficiency of the system.

- Less the Power greater the efficiency.

- Minimum Water Supply is also a prime responsibility and requires all infrastructure to work without fail.

Solutions and Tech Components

Use of technology in the infrastructure

- To monitor the pre-alarm condition of Motor failure AI based programming with smart sensor technology will help.

- Any Power supply related issues to be monitored

- Various factors affects the motor life and leads to failure.

- Vibration of motor

- Winding/body temperature of motor

- All Power parameters i.e. Voltage, current, PF etc.

- Pump efficiency measurement with Temperature, pressure, Head, Flow, etc.

Pump Efficiency Monitoring by using

Pump Energy Reporter Module

- Base Line Calculator

- Energy report

- Pumping cost this hour, last hour, today, yesterday, last week, last month (KWh/m3, Cost per m3)

- GHG Emission Report (GHG Gas emission today,Yesterday, last week, last month )

CASE STUDY:

This affect was seen system wide when implemented for a customer…

Lean Architecture and Features:

Intelligent Remote Terminal Unit is connected with various field sensor wired or wirelessly Field sensors connected with iRTU for different parameters monitoring are e.g

- Vibration and temperature sensor—For Motor failure prediction

- Camera or AI based sensor-Leakage inside Pump house

- AI based Edge solutions – Panel monitoring via. Actual status of lamps and panel conditions

- Pressure, Flow and temperature parameters for Pump efficiency monitoring

iRTU will connect via. GPRS (or various wireless communication technology NB-IOT, LoRa Wan, etc.) with Master Control station SCADA software (WebSCANET) and WebSCANET will send data through API or OPC-UA to ICCC software.

ICCC software can have below integration:

- Water Management software

- Water Quality data (residual Chlorine, pH, Turbidity parameters)

- GIS survey mapping on google map interface.

- Hydraulic data

ICCC DASHBOARD

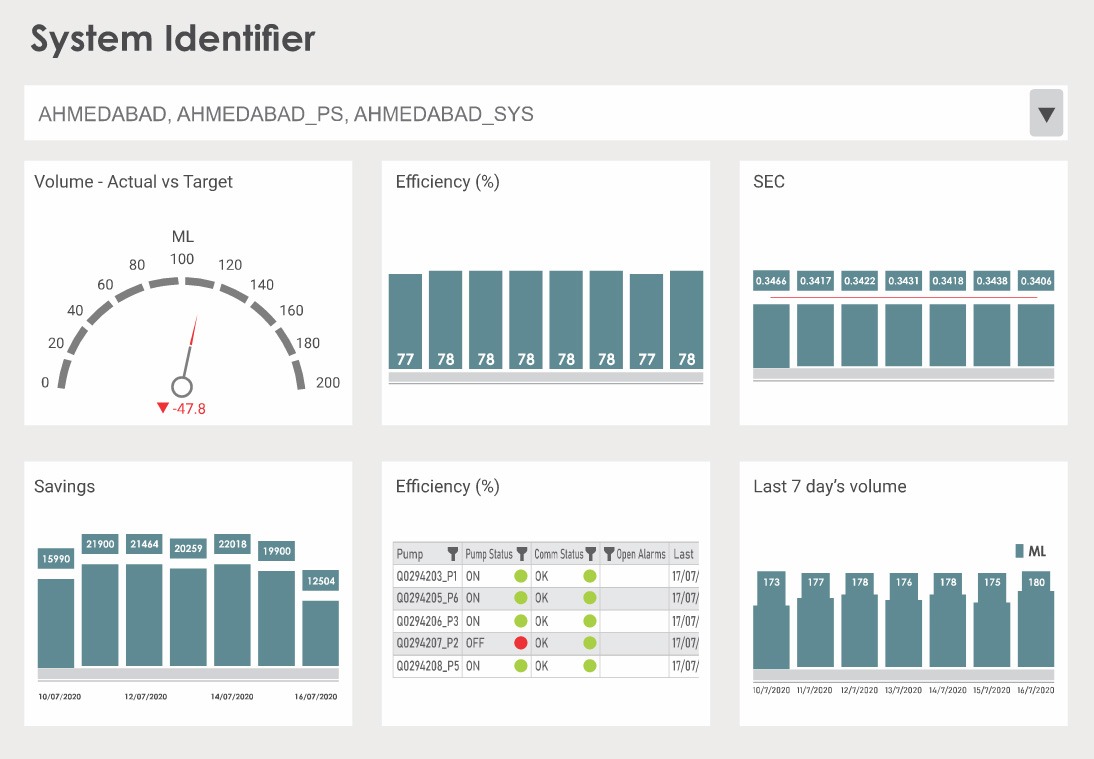

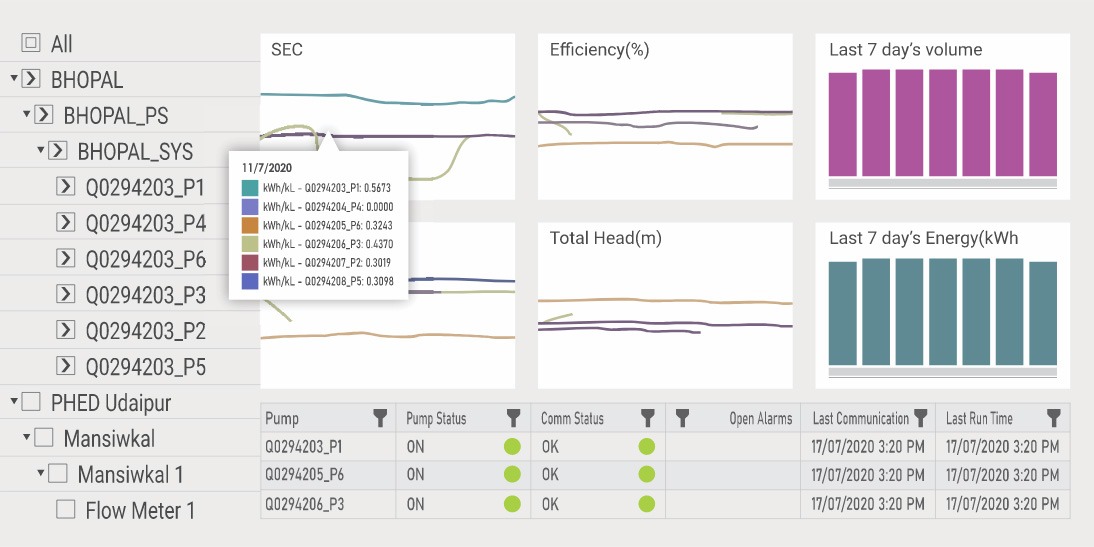

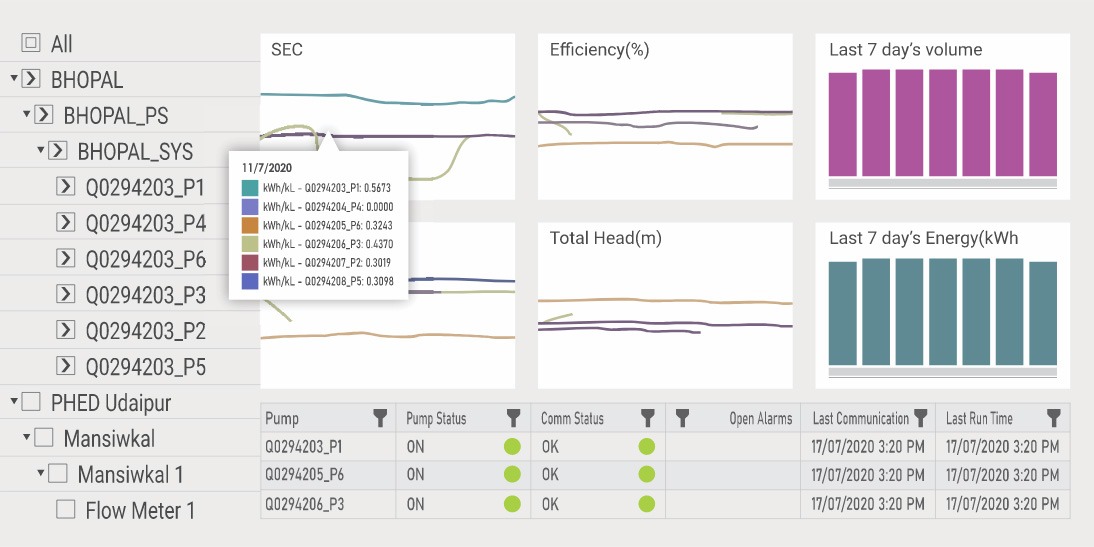

Key Performance Indicators (KPI)

- Plot Dial Graph for Required daily Flow dial vs Actual Flow on Present day

- Bar Graph: Last Seven days Total Volume distributed

- Bar Graph: Last seven days Energy consumption data

- Bar Graphs : KWH/KL for 7 days Bar graph: % Efficiency of Pump per day (Average) or Pump wise

- Bar Graph: Total Energy Saving Per day (Base Line consumption – Actual Consumption)/ Base Line consumption

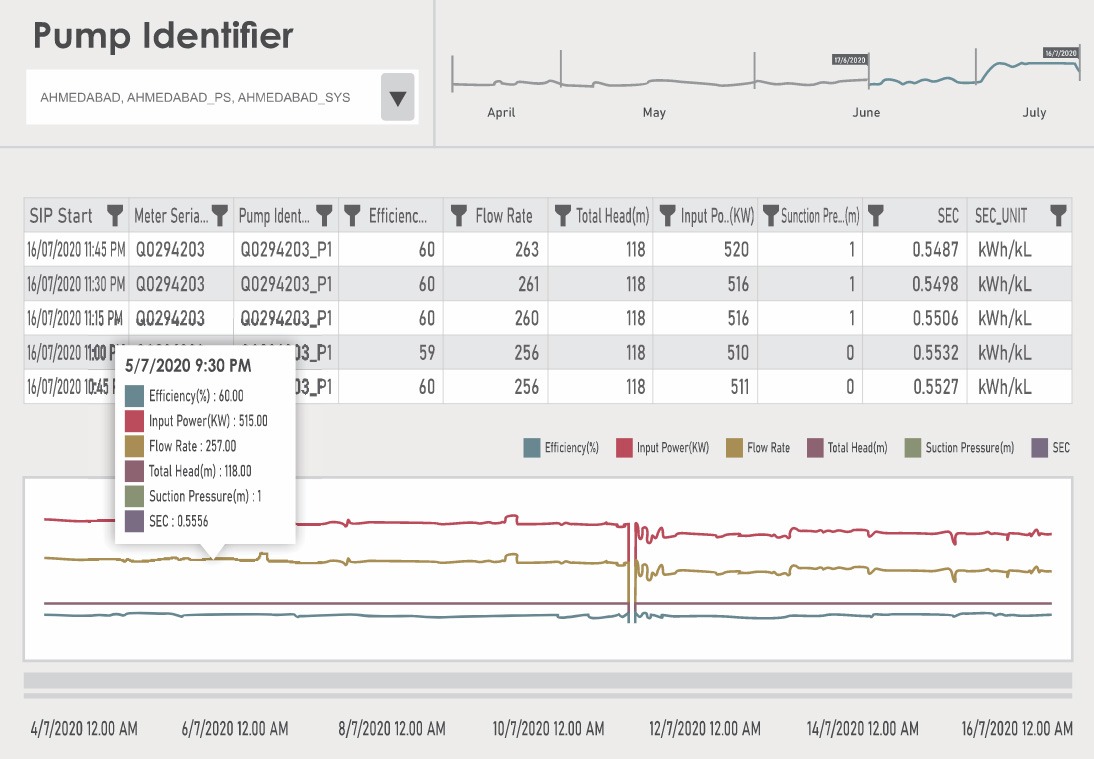

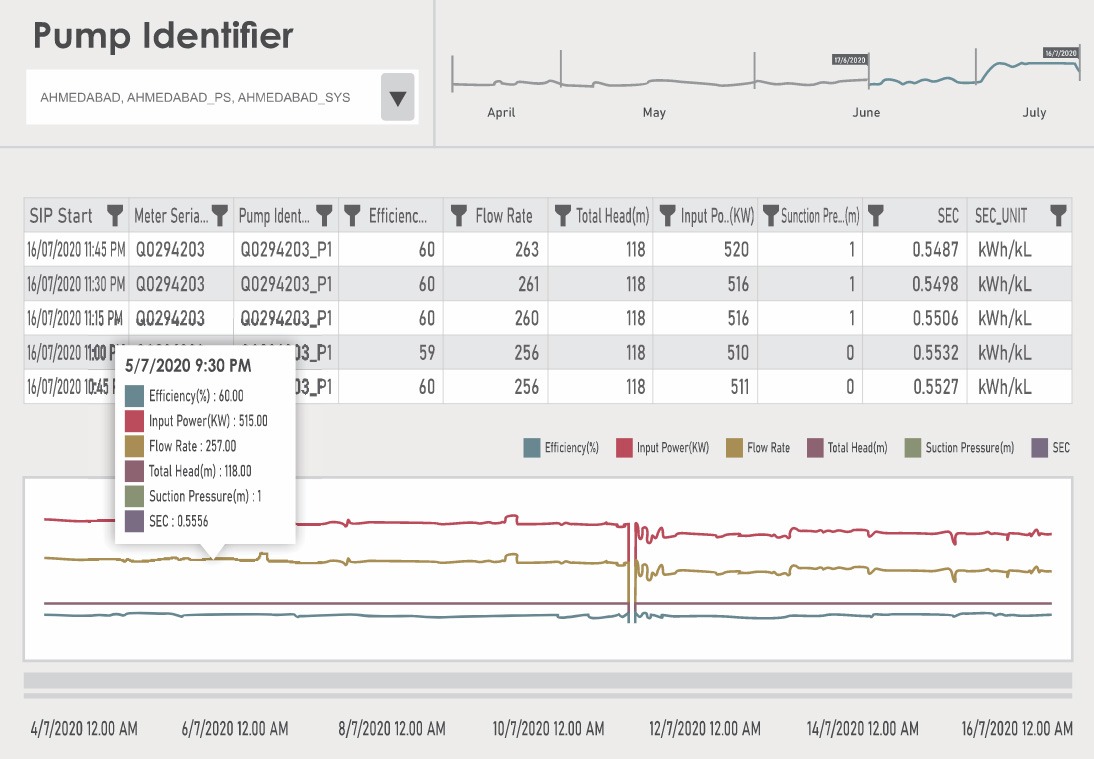

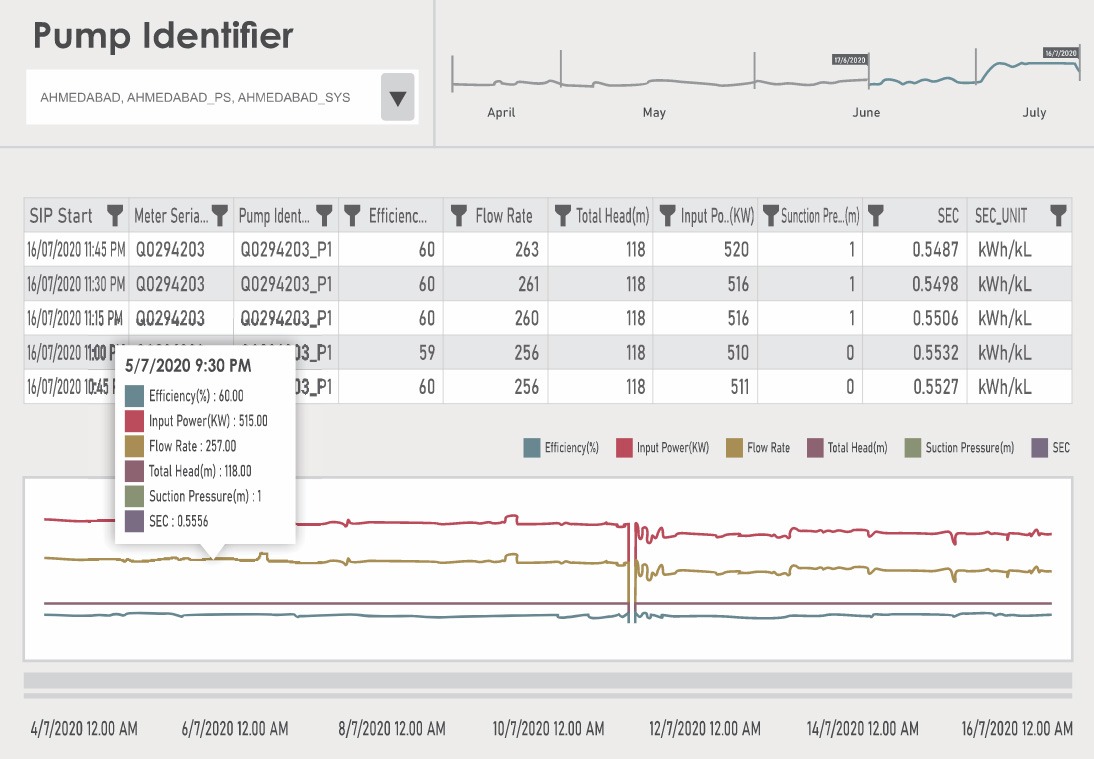

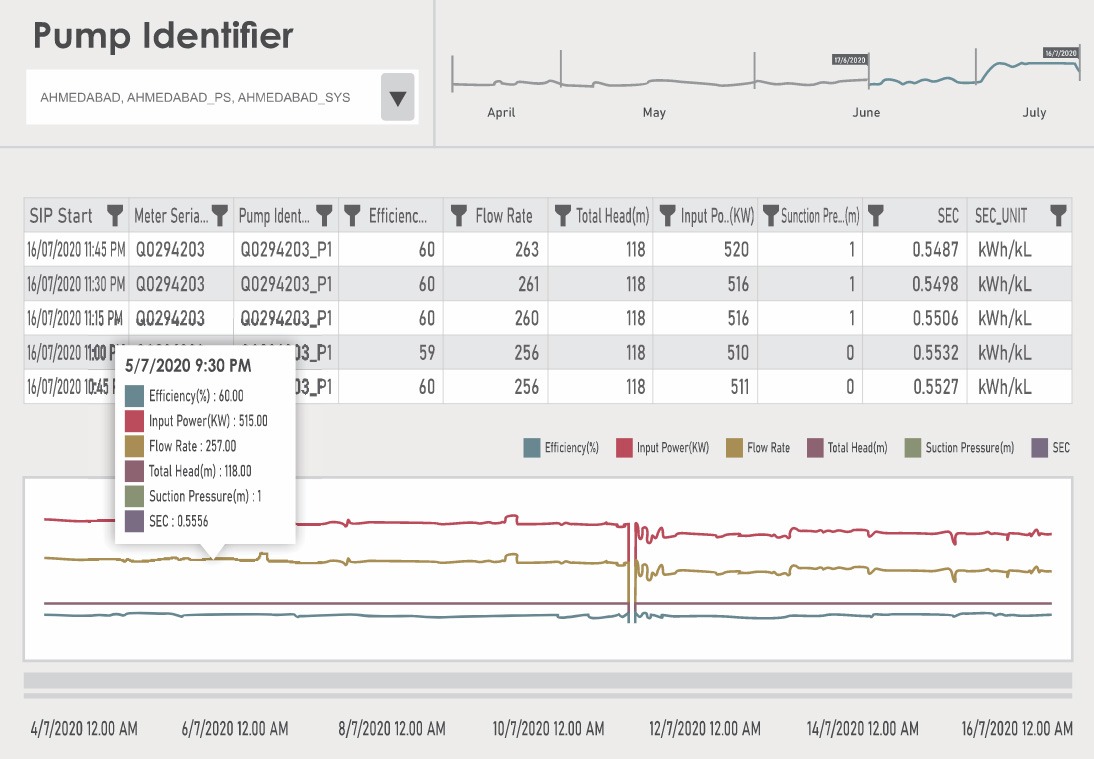

Performance Trends:

Values in Tabular form and Online trends of following parameters:

- Motor and Pump Sr. No.

- Efficiency

- Flow rate

- Total Head

- Total Power consumption

- Discharge pressure

Group Performance

Values in Tabular form and Online trends of following parameters:

- Total Efficiency

- Total Head

- Total Power consumption

- Total Volume

Manufacturer Curves

- Manufacturer Pump and Motor data sheet and curves with asset details

- Attributes if all mapped elements like Type/Model/ Mfr/ Vintage/ Ratings of Pumps, starters etc. Size/ Type/ MOC/ Vintage of pipes, staging/capacity of GLSRs/

- ELSRs etc. shall form the exhaustive database of the Asset Management software.

- Provision for dynamic addition of new assets and deletion of discontinued assets.

- Provision of update on existing assets (like increase in capacity, pipe diameter changes etc.

- Provision of automation entries Valves, Pressure, Flow, Level instrument details.

- Provision of upload of documents like manuals, drawings, excel sheet etc.

Alarms

- All alarm conditions related with motor trip/fail conditions

- Alarms related with Pump efficiency below set points

- Alarms related with Total KWH increases or volume increases

- Pre-alarm conditions and Power parameters alerts