Test Article

CIMCON Celebrates Milestone: Smart Lighting Illuminates Mumbai Atal Setu

CIMCON proudly announces the completion of its latest milestone: the implementation of smart lighting innovation on India’s largest sea bridge, the Mumbai Atal Setu. This remarkable achievement not only elevates safety standards but also champions sustainability efforts on this iconic infrastructure.

Thanks to CIMCON’s cutting-edge smart lighting solutions, the Mumbai Atal Setu now boasts enhanced illumination, ensuring optimal visibility and safety for commuters and pedestrians traversing its expanse.

Our unwavering dedication to excellence in engineering and sustainability has positioned us as a pivotal player in the transformation of critical infrastructure throughout India.

We are thrilled to have contributed to this groundbreaking project, which not only enhances urban landscapes but also promotes sustainable development initiatives.

A heartfelt acknowledgment goes out to our dedicated team and all stakeholders whose collaboration has been instrumental in the success of this project. Together, we illuminate the path toward a brighter future for India’s infrastructure landscape.

Capturing Moments: Glimpses of the Event

In a groundbreaking showcase at the Smart Cities India Expo held from January 17th to 19th, 2024, our participation was marked by the unveiling of cutting-edge smart solutions designed to revolutionize urban living.

Visitors to our booth, located at E309 in Hall 1 of Pragati Maidan, were treated to a comprehensive array of innovative solutions tailored for Smart Cities, Smart Water, Smart Manufacturing, and Smart Lighting. The event aimed to explore the future of intelligent urban development, where technology seamlessly integrates with daily life.

The Smart Cities India Expo 2024 showcased not only our commitment to advancing urban development but also our dedication to providing solutions that make cities smarter and more sustainable.

Capturing Moments: Glimpses of the Event

We were honored to be active participants at the 3rd edition of the Industrial Process Optimization & Safety Conference Expo (IPOS 2023) alongside CIMCON. At this event, our industry experts Prashant Kapadia, Ishu Rastogi, and Rakesh Patel guided the oil and gas industry through the realms of digital transformation. It was an opportunity for attendees to delve into innovations that promise to reshape the landscape of industrial processes.

The conference took place on December 15-16, 2023, at Radisson Blu, Dwarka, New Delhi. We occupied Booth No: B1, where we showcased the future of efficiency with TLP Monitoring, provided insights into the digital transformation in TR, guaranteed asset longevity through Cathodic Protection Monitoring, facilitated seamless oil production optimization with SRP Monitoring, and presented transformative strategies for asset management.

Capturing Moments: Glimpses of the Event

We are thrilled to be a part of the Engineer Conclave #ECIDS2023 at Manekshaw Centre, New Delhi, where visionaries, experts, and innovators gathered to pave the way for a sustainable future in infrastructure development.

The discussions were as diverse as the skyline we aim to shape—covering sustainable practices, cutting-edge technologies, and collaborative efforts to build resilient, smart cities.

Check out these snapshots capturing the essence of innovation and collaboration that filled the expo halls! Swipe left to witness the incredible strides being made in engineering excellence.

We are grateful for the Engineer-in-Chief’s special gesture, presenting us with a memento at #ECIDS2023 for our participation and contribution!

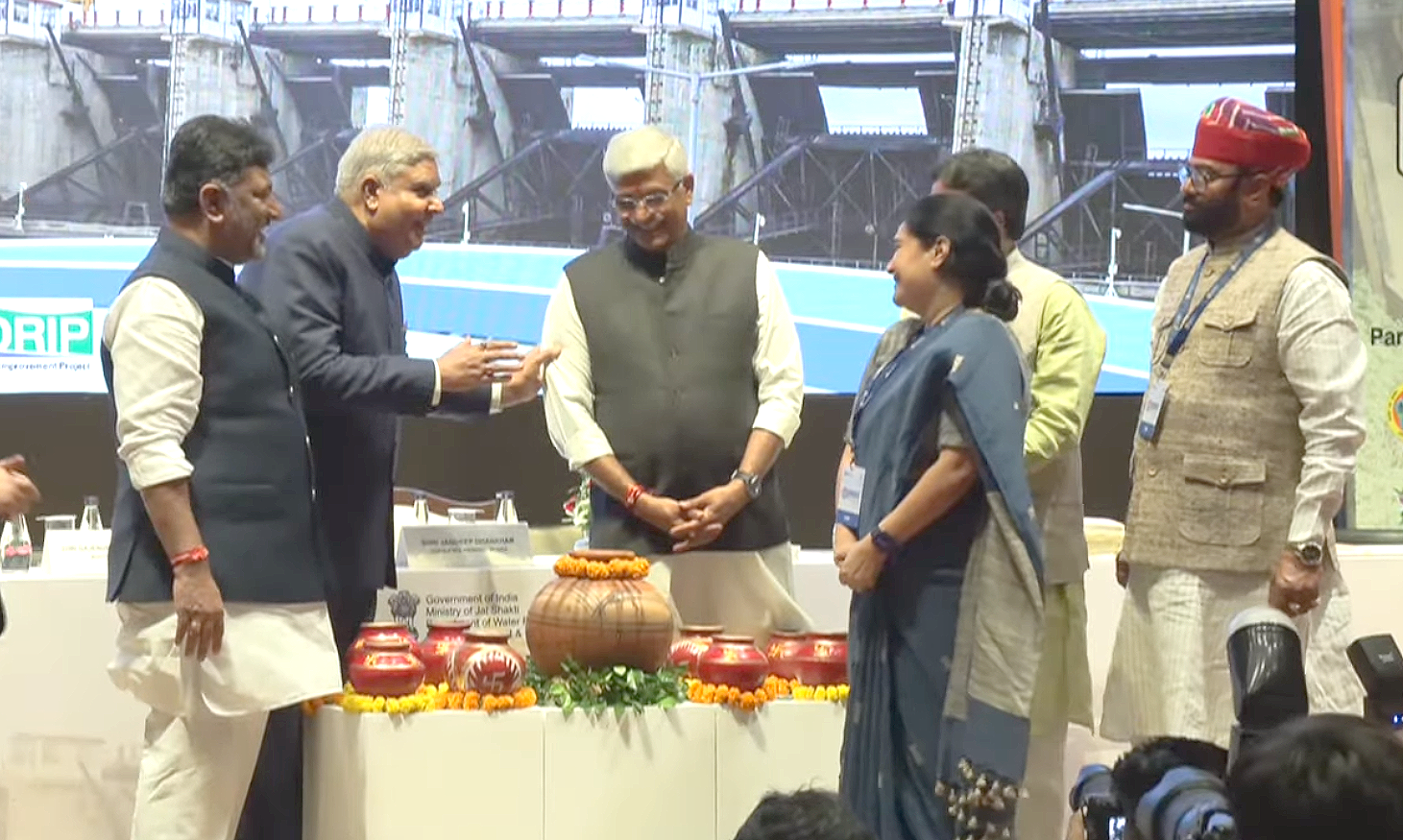

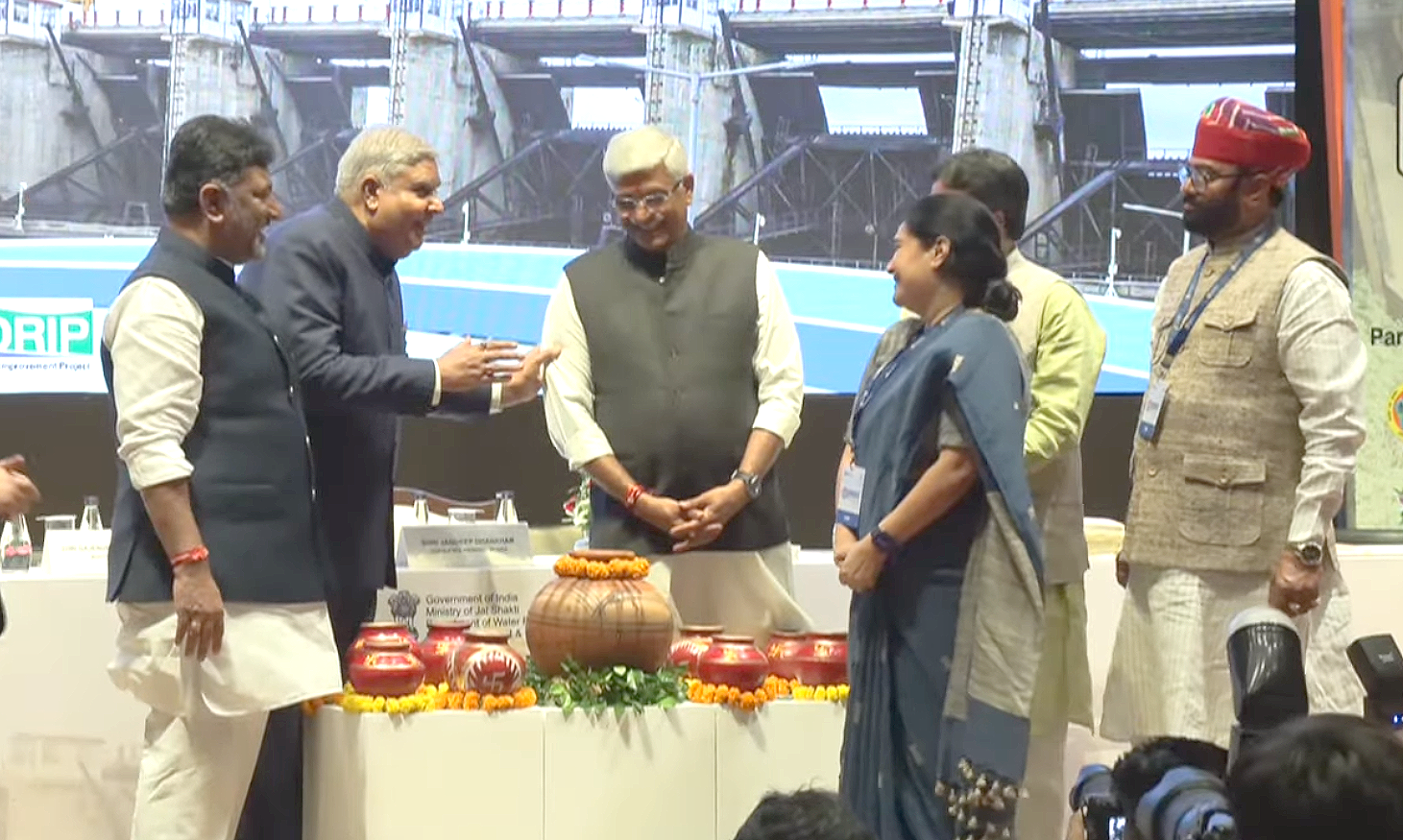

Capturing Moments: Glimpses of the Event

CIMCON had the privilege to participate in the International Conference on Dam Safety 2023. The event, which took place on September 14th and 15th 2023, brought together dam safety experts and stakeholders from around the world to discuss crucial topics related to dam safety, maintenance, and management. The event, organized by the Department of Water Resources, River Development & Ganga Rejuvenation, Ministry of Jal Shakti, Government of India in collaboration with the Rajasthan Water Resources Department, Central Water Commission, National Dam Safety Authority, MNIT Jaipur, WAPCOS Ltd, World Bank and the AIIB. The Conference is supported by reputed organizing partners, academic partners, DRIP Implementing Agencies, sponsors and media partners.

The International Conference on the theme “Safe & Secure Dams Ensure Nation’s Prosperity” was inaugurated by the esteemed Vice President of India, Shri Jagdeep Dhankhar

Our team at #CIMCON had the opportunity to showcase our innovative solutions and share insights on enhancing dam safety and resilience. We are committed to pioneering technologies that ensure the integrity of critical infrastructure.

For more details about the event, please visit website: https://icds2023.in

Capturing Moments: Glimpses of the Event

The water industry has been facing challenges since years in terms of ageing population, population growth and rise in energy consumption. To counter the same, many water plants have started adopting digital technologies in order to improve efficiency and get rid of manual work. CIMCON has been helping the cities and water plants for years in order to achieve maximum efficiency and reduce the manual labor to improve operational efficiency. Check out our article published in Water Digest Magazine 2023 where we have emphasised on the fact that how much digital technologies are needed to improve the water system and how we have helped the city of Uttarakhand to improve efficiency in water generation inspite of harsh weather and conditions.

The global research and advisory firm, Gartner defines digitalization as “the use of digital technologies to change a business model and provide new revenue and value-producing opportunities; it is the process of moving to a digital business.”

Traditional water and wastewater systems were built decades ago. Due to the changing stresses of climate and rapid urbanisation, water and wastewater systems cannot keep up. The ageing infrastructure brings with it risks of potential failure and poor environmental compliance. These issues are key concerns for municipalities around the world.

More than ever, water treatment operators across the world are turning to digital solutions to transform their day-to-day business outcomes. The latest digital technologies are not only helping industry become more efficient and effective but also transforming the way the water industry creates and captures value. Therefore, it is imperative that companies strengthen their core competencies with an eye on the future and understand how the digital journey will ultimately transform the relationship between customers and providers.

Municipalities face challenges when looking to accelerate the adoption of digital water technologies. There is the challenge of overcoming data silos and of integrating systems, especially legacy systems. There are human resources challenges as well as a need to clearly define the return on investment of new systems. Some of the common challenges are listed below.

The state of rapidly deteriorating water infrastructure is a known issue, driven by inadequate investment in rehabilitation and replacement of equipment and facilities. This matter weighs heavily on the minds of the industry professionals–according to Black & Veatch’s annual survey of water, wastewater, and stormwater professionals, nearly 80 percent of water plants respondents see ageing infrastructure as the most challenging issue facing the industry today.

In municipal wastewater treatment plants 50-60 percent of the energy is used to operate the wastewater and other plants. It is estimated that the plants consume 60 terawatts-hour every year. Due to the large energy consumption, a lot of the time focus is on reducing the energy consumption to effectively run the plants throughout the year.

Population growth and urbanisation put an extra load on aging systems. The first challenge of urbanisation is meeting supply demands. The second is in maintaining water quality and reducing environmental pollutants because of urban spread.

Access to digital control means using IoT-supported, data-driven models that integrate and optimise smart pumps, valves, sensors, and actuators. Digital controls also enable devices to “talk” to each other, send data to your smartphone, and produce real-time information that can be accessed and shared over the cloud. Municipalities can analyse, automate, correct, and predict risks in real time by adopting digital infrastructure. This will equip them to address many of the current challenges they face, including extending the life of aging assets, reducing leaks, thwarting cyber-attacks, and preventing other abnormalities in the distribution network service levels. This increases the reliability of supply, promotes water conservation, and increases revenue through operational efficiencies.

The following are some further benefits of adopting digital technologies:Digital solutions such as a dense network of sensors, intelligent equipment, real-time source-to-tap digital twins, data analytics, and advanced simulation tools enable municipalities to be better prepared for their changing environments. By improving day-to-day water management and building long-term resilience to disasters and climate change, digital solutions address municipalities’ priorities.

Digitalization of water management is a huge leap for both infrastructure and society. It will put an end to many hassles and inefficiencies associated with older equipment. Increased efficiency positively impacts the customer. Digital solutions such as detecting leaks, excess vibration, pump bearing failure, cavitation and asset management platforms can provide preventive and predictive maintenance capabilities which can help reduce downtime of critical assets and maximise effectiveness and efficiency of operations.

With the advent of the digital revolution in the water industry, data collection and exchange are growing exponentially, replacing traditional methods and practices. Being able to monitor machines, pumps, and other instruments in the water sector as well as collecting precise data is hugely advantageous for water management.

To reap the full benefits of digitalization, companies in the water industry must follow global standards for connectivity, data storage, data availability, and legislation as well as provide ways to easily integrate their system with other systems. Thus, new water technology systems need to be developed based on new data sources, more intelligent products, and robust planning tools. There is also a need for more service-based business models, collaborative systems based on intelligent water technology components, and multi-utility systems that combine water treatment, energy, and resource recovery in a cyber-safe framework. Hence, having the right products together with an understanding of customer needs and applications combined with intelligent connectivity, are key factors for success in the water industry for the years to come.

Water treatment plants face some common challenges in manual labour due to leakage of pipes and valves to electrical and mechanical instruments. Add to that the energy consumption and there is a huge challenge that needs to be addressed. With digitalization, water treatment plants can not only automate the processes but can also manage the assets in real-time and can work on strategies to minimise wastage and maximise purity of outgoing water.

Water generation plants also face challenges with the ageing infrastructure coupled by reduced ground water level and surface water not being chanellised. With proper digitalization, the plants can reduce maintenance and operation costs improve the product quality and increase productivity to enable timely decision making and better process control.

Water distribution plants face some common challenges with physical loss of water due to leakage and wastage and decrease in water pressure, which leads to degrading the water quality. With the help of digitalization, water distribution plants are able to reduce the wastage of water maintain the quality of water with proper monitoring of the assets in place to enable efficiency.

The sewage plants also face challenges in operation with high energy consumption and with shortage of manpower, there are ill effects on environment with no proper management in place. With digitalization, the plants can not only reduce the energy consumption but also automate the processes to counter the shortage of manpower and manage the assets in real-time.

While digital water technology offers considerable promise, there are challenges in scaling adoption of these technologies. One of the main challenges is workforce capacity and training.

Whether the issues are real or perceived, the water sector is slow to adopt new technologies due to a lack of incentives, the risks of adopting new products, and individuals being siloed in their own department. As a result, proven technologies are strongly favoured over unproven or emerging technologies in the water industry. In general, water workforces are not trained in digital technology solutions. This type of training is necessary to scale the adoption of digital technologies.

CIMCON’s Remote Terminal Units or RTU’s and SCANET Software systems has helped cities and municipalities efficiently deliver water and wastewater treatment for over 30 + years. With CIMCON’s vast experience in the water sector, these training and staffing issues are resolved. Instead of having to re-train the workforce in new technologies, CIMCON guides the water departments by taking care of the IoT Part in managing their assets in a better, more efficient manner.

Uttarakhand, a northern states in India is known for its beautiful natural environment of the Himalayas and is also referred to as “Devbhumi” or the land of Gods. The government of Uttarakhand had given a contract to the Uttarakhand Peyjal Nigam to provide drinking water to 40,000 villages in the Uttarakhand district which are spread far and wide across the mountains and difficult terrain. The mission was to provide proper drinking water to one crore citizens.

Being a hilly area, pumping stations are deployed for proper generation of water. But there were quite a few challenges in the pumping stations. In some extreme weather conditions, the pumping operators were not able to reach the pumping stations. Also, the operators used to handle the pumping stations manually, which led to loss of time and water not being pumped at regular intervals. All these challenges followed by manual intervention led to operators not following whether the overhead tanks were full or not, which led towater mismanagement.

Due to all these issues, Peyjal Nigam implemented CIMCON’s wireless remote monitoring solution to tackle the challenges. The remote terminal units along with CIMCON’s SCADA Systems were all connected with the central monitoring systems of the Peyjal Nigam and through GSM technology the operators of the Peyjal Nigam were notified about water issues through messages. Through CIMCON’s remote monitoring solutions, the flow, the level and the pressure of the water pumps can be measured effectively and reduced manual intervention with time.

Post implementing the solutions, Peyjal Nigam not only was able to manage the pumps effectively, but improved the efficiency of the pumps and reduced downtimes with proper interventions leading to improved productivity. CIMCON’s Remote Terminal Units and SCADA systems not only helped the water system to be managed automatically but alerts were generated earlier so that the field workers can go there and rectify the issues if needed. This has helped Peyjal Nigam in saving water and energy consumption by 60 percent and improving productivity by 40 percent.

The water department has made great strides in the uptake of digital technology. However, there is still plenty of room for improvement. Since technology has evolved, it is possible to take a great leap forward to achieve true digital transformation with minimal investment. Water departments need to start with a clear strategic plan to create a full digital ecosystem. This can start by dividing the water network into discrete zones and identifying what is needed to address the specific challenges in each. Effectively, it is best to start small by adding to existing technology. CIMCON can do this through connecting to a variety of existing water instruments without having to invest in new, expensive systems. Our product uses wired and wireless networks to communicate with water assets distributed over a large geographical area throughout a city. Then, it communicates this data back into the cloud using available network.

So, is digitalization hard to implement? With CIMCON’s experience in the water industry and its wide range of solutions from hardware, software, SCADA and the latest predictive maintenance solutions with AI and ML technologies, digitalization has never been easier to implement.

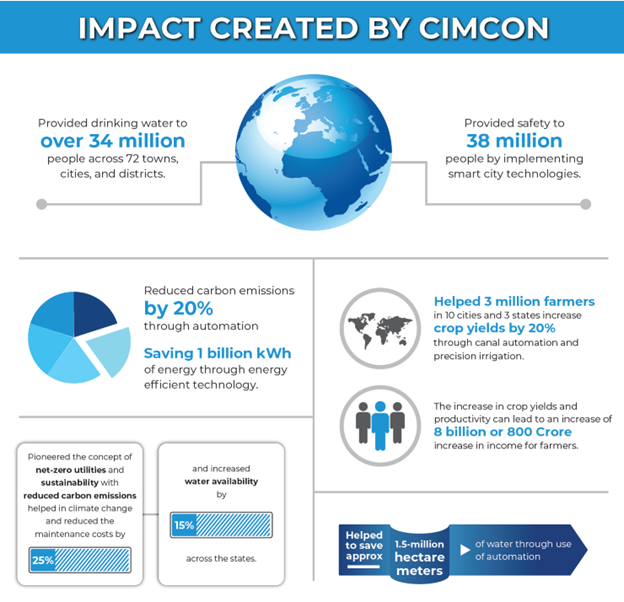

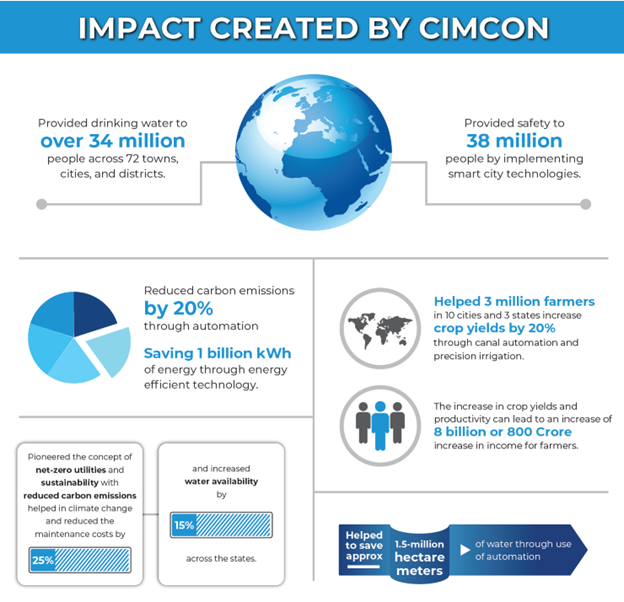

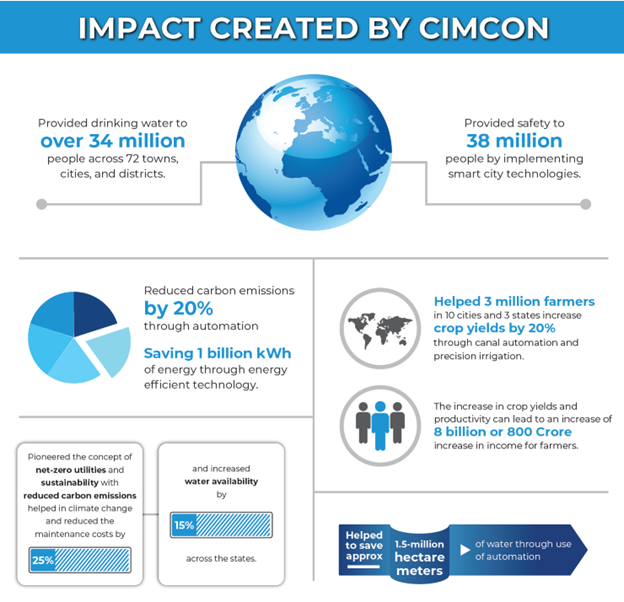

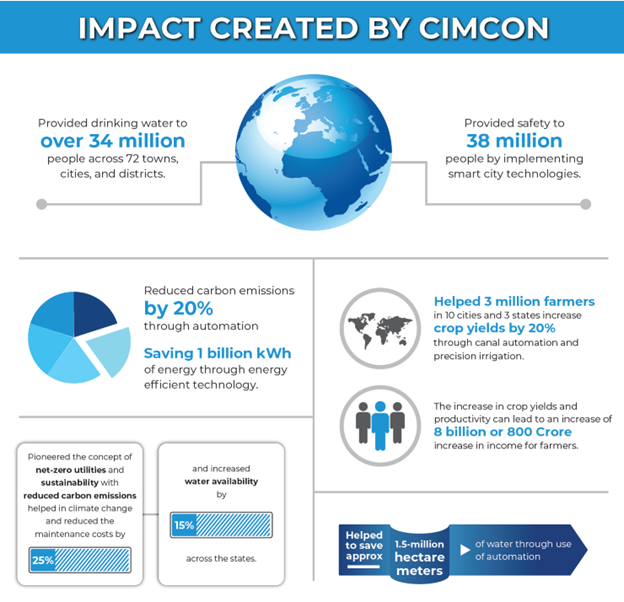

This year, a world-leading technology company will mark 37 years of making an incredible impact on society – and transforming the lives of millions of Indians.

In India, CIMCON Automation has introduced innovative systems in water, oil, energy, defense, and agricultural sectors, whilst also contributing massively towards protecting the environment

The company’s ‘smart’ automated technologies have directly led to the provision of drinking water to over 34 million residents across 72 towns, cities, and districts in India.

Read the full article : https://smartwatermagazine.com/news/cimcon/cimcon-dedicates-37-years-transforming-lives-millions-indians

Software solutions for lighting have provided safety for 38 million people across the country, while carbon emissions have been reduced by 20% through automation, saving 1 billion kWh of energy through energy-efficient technology.

Three million farmers in 10 cities and three states were aided in increasing their crop yields by 20% through canal automation and precision irrigation, which was led by CIMCON. The increase in crop yields and productivity is expected to result in an $8 billion rise in income for farmers.

Anil Agrawal, CEO of CIMCON, said: “At CIMCON, we believe in utilizing technology to solve real-world problems and make a positive impact on society.

“We are dedicated to transforming the way our clients do business by delivering game-changing solutions that enhance safety, increase efficiency, and drive cost savings across multiple industries”.

With a highly experienced team of engineers and managers, CIMCON continues to lead the way in the next generation of industrial automation.

CIMCON has been in the automation market for several decades and has tried to address challenges related to ageing infrastructure, population growth, and increasing energy consumption. These real-world problems have led to a greater need for innovative solutions to improve efficiency. CIMCON Automation has been working towards finding solutions to these challenges with its experienced team and has made several inventions that have improved the efficiency of the water, oil and gas, and energy sectors over time. Despite the challenges faced, CIMCON has remained dedicated to developing sustainable and efficient solutions to help address the ongoing issues in the automation sector.

The company has come a long way from its humble beginnings in 1986, when Anil Agrawal founded CIMCON Automation in Ahmedabad with a vision of revolutionizing automation and bringing it to the forefront of technology in India.

With a mission to improve energy efficiency and enhance the quality of life for urban residents, CIMCON has been instrumental in introducing innovative technologies that have transformed the way the country operates.

Today, CIMCON is a global leader in the field of smart water, smart city and smart oil & gas technology.

CIMCON began its operations in the rapidly developing city of Ahmedabad, with the goal of revolutionizing the way the city managed its electricity distribution. In 1991, the Ahmedabad Electrical Company (now called Torrent Power Ltd.) became the first to utilize CIMCON’s electrical SCADA system, which allowed them to remotely monitor and control the power supply and distribution for the entire city.

CIMCON’s growth in the first project for Torrent power led to various projects for the next three decades, including entering the oil and gas industry for cathodic protection, SRP well, liquid and gas flow monitoring.

The efficient and effective automation systems were then utilized in projects for public water treatment, distribution, generation, and sewage plants by managing the water well, pumps and various other assets in the water industry. This has been crucial for delivering clean water to millions of people across even the most remote areas within India.

CIMCON’s wireless remote monitoring solution surveils drinking water systems in remote villages in real-time. RTUs connected to a central system monitor flow, level, quality, and pressure, reducing manual intervention and improving water efficiency. Level sensors alert operators when water levels are too high or low and water quality sensors measure physical, chemical, and biological parameters to maintain water quality.

CIMCON’s high-tech water solution is being utilized in several states across India, including Chhattisgarh, Gujarat, Haryana, Himachal Pradesh, Uttarakhand, Uttar Pradesh, Punjab, as well as the Military Engineering Services Division. In Uttarakhand, CIMCON has helped the government provide proper drinking water to 40,000 villages which are spread far and wide across the mountains and difficult terrain. Initially without CIMCON solutions, the field workers used to climb hills in all adverse weather conditions to turn on the pumps and also check when the pumps were down. Sometimes due to weather conditions, the field engineers were not able to reach the location for days. With CIMCON Solution, the engineers can control the pumps and machines remotely and also analyze the faults in the Remote Monitoring center. This has helped the state to not only reduce the manual labor but also take proactive actions based on the inputs from the CIMCON SCADA system.

CIMCON’s canal automation project has been a game changer for farmers, enabling them to increase crop yield and diversify into commercial crops without worrying about water supply. This has helped farmers to earn more revenue per hectare of land, thereby improving their financial status. In addition, CIMCON’s automation project has addressed water issues in cities where water problems existed.

CIMCON’s solution allows for accurate control of water flow even in the absence of operators. With proper timers, the system can distribute water judiciously, reducing water losses and increasing crop productivity. The project has also helped farmers to grow crops in a more efficient manner, with better use of water resources. This not only leads to increased crop productivity but also promotes sustainable agriculture.

By improving the efficiency of the system, CIMCON has helped to reduce the manual labor required to manage the canal, freeing up farmers to focus on other tasks. With the system’s remote monitoring capabilities, farmers can easily monitor the canal’s operations and make necessary adjustments from a central location, without having to travel to the canal site.

Overall, CIMCON’s canal automation project has been a major success, benefiting both farmers and cities. By improving water efficiency, reducing losses, and increasing crop productivity, CIMCON has helped to improve the quality of life for farmers and promote sustainable agriculture in the region.

With its ‘Smart Cities’ mission, CIMCON has also helped in various smart lighting projects in India in order to improve energy efficiency. The company managed smart streetlights in various cities including Ahmedabad, Aurangabad, Chennai, Gift, Gandhinagar, Hyderabad, Jaipur, Kakinada, Khargaon, Ladwa, Noida, Nagpur, Ooty, Pehowa, Raipur, Shahabad, Solapur, Thanesar, Vadodara, Vizag and others along with multiple defense establishments. Similar power projects have also been completed by the company in the Middle East, including in the UAE and Qatar. In the city of Vadodara, CIMCON is helping to replace 12,000 old lights with smart LED lights with remote monitoring which will help the Vadodara government to manage the lights remotely and also assure the citizens of living in a healthy and safe environment. Due to these initiative, Vadodara is now ranked one of the top 5 cities in the Smart Cities mission

In addition to implementing effective systems in power supply, water provision, and agricultural production, CIMCON has also provided specialist automation in areas including national defense and space research.

The evolution of CIMCON over the years has resulted in the company playing an important role in the defense and security of India by providing a wireless intruder, fire, and environmental alarm system for defense establishments to ensure proper storage and monitoring of artillery. These systems were installed in multiple locations including Naliya, Bhuj, Jamnagar, Jodhpur, Jaisalmer, Jorhat, Chabua, Bagdogra, Pune, and West Bengal.

For National Space programs, CIMCON provided a mission-critical PLC control system at the Space Applications Centre (SAC) of Indian Space Research Organization (ISRO) in Ahmedabad.

In the oil and gas industry, CIMCON pioneered the innovative cathodic protection system which was used for central monitoring by renowned petroleum and gas companies such as Saudi Aramco, GAIL, and IOCL. This method offered 24/7 protection of stations, a 30% reduction in monitoring costs, improved planning activities through early identification of issues, and flexibility in carrying out surveys. CIMCON also introduced the innovative concept of “Speaking well” for electronic surveillance of SRP wells for ONGC.

After nearly four decades of automating systems and saving time, money, and energy in major industries, CIMCON remains committed to customer satisfaction by following NABL-accredited testing procedures and achieving ZED and TÜV SÜD certifications for the safe, high-quality production of their remote terminal units.

CIMCON has established offices in Agra, Chandigarh, Dehradun, Lucknow, Noida, Pune, Raipur, Vadodara, and a research and development facility in Ahmedabad. By utilizing state-of-the-art technology, CIMCON continuously improves processes and develops new products to remain a leader in the global market. With three decades of experience and global exposure, CIMCON is committed to improving the automation journey of its clients, helping them to achieve greater operational efficiency and reduce losses. CIMCON prioritizes customer feedback, and its products are designed according to customer requirements. With a highly efficient R&D team, CIMCON not only develops and improves products but also anticipates industry needs and trends to ensure they remain at the forefront of automation innovation for the global market.

There are numerous CIMCON projects that have made a positive impact on society and improved the lives of Indians nationwide, and these efforts have helped the company gain recognition for its innovative and excellent work, and its tremendous impact on the Indian economy.

The water industry has been facing challenges since years in terms of ageing population, population growth and rise in energy consumption. To counter the same, many water plants have started adopting digital technologies in order to improve efficiency and get rid of manual work. CIMCON Digital has been helping the cities and water plants for years in order to achieve maximum efficiency and reduce the manual labor to improve operational efficiency. Check out our article published in Water Digest Magazine 2023 where we have emphasised on the fact that how much digital technologies are needed to improve the water system and how we have helped the city of Uttarakhand to improve efficiency in water generation inspite of harsh weather and conditions.

Read the full article: https://thewaterdigest.com/case-study-digitalisation-of-water-industry-helping-uttarakhand-in-improving-water-efficiency/

The global research and advisory firm, Gartner defines digitalisation as “the use of digital technologies to change a business model and provide new revenue and value-producing opportunities; it is the process of moving to a digital business.”

The digitalisation of the water industry means adopting a smarter approach to water generation, water distribution, and water treatment. Digital technologies offer unlimited potential to transform the world’s water systems, helping Water departments become more resilient, innovative, and efficient as well as empowering them to use more cost-efficient processes.

Traditional water and wastewater systems were built decades ago. Due to the changing stresses of climate and rapid urbanisation, water and wastewater systems cannot keep up. The ageing infrastructure brings with it risks of potential failure and poor environmental compliance. These issues are key concerns for municipalities around the world.

More than ever, water treatment operators across the world are turning to digital solutions to transform their day-to-day business outcomes. The latest digital technologies are not only helping industry become more efficient and effective but also transforming the way the water industry creates and captures value. Therefore, it is imperative that companies strengthen their core competencies with an eye on the future and understand how the digital journey will ultimately transform the relationship between customers and providers.

Municipalities face challenges when looking to accelerate the adoption of digital water technologies. There is the challenge of overcoming data silos and of integrating systems, especially legacy systems. There are human resources challenges as well as a need to clearly define the return on investment of new systems. Some of the common challenges are listed below.

HOW DIGITALISATION IMPROVES THE WATER INDUSTRY Access to digital control means using IoT-supported, data-driven models that integrate and optimise smart pumps, valves, sensors, and actuators. Digital controls also enable devices to “talk” to each other, send data to your smartphone, and produce real-time information that can be accessed and shared over the cloud. Municipalities can analyse, automate, correct, and predict risks in real time by adopting digital infrastructure. This will equip them to address many of the current challenges they face, including extending the life of aging assets, reducing leaks, thwarting cyber-attacks, and preventing other abnormalities in the distribution network service levels. This increases the reliability of supply, promotes water conservation, and increases revenue through operational efficiencies.The following are some further benefits of adopting digital technologies:

Digital solutions such as a dense network of sensors, intelligent equipment, real-time source-to-tap digital twins, data analytics, and advanced simulation tools enable municipalities to be better prepared for their changing environments. By improving day-to-day water management and building long-term resilience to disasters and climate change, digital solutions address municipalities’ priorities.

THE WAY FORWARD TO FULLY DIGITALISED WATER INFRASTRUCTURE To reap the full benefits of digitalisation, companies in the water industry must follow global standards for connectivity, data storage, data availability, and legislation as well as provide ways to easily integrate their system with other systems. Thus, new water technology systems need to be developed based on new data sources, more intelligent products, and robust planning tools. There is also a need for more service-based business models, collaborative systems based on intelligent water technology components, and multi-utility systems that combine water treatment, energy, and resource recovery in a cyber-safe framework. Hence, having the right products together with an understanding of customer needs and applications combined with intelligent connectivity, are key factors for success in the water industry for the years to come.

While digital water technology offers considerable promise, there are challenges in scaling adoption of these technologies. One of the main challenges is workforce capacity and training.

Whether the issues are real or perceived, the water sector is slow to adopt new technologies due to a lack of incentives, the risks of adopting new products, and individuals being siloed in their own department. As a result, proven technologies are strongly favoured over unproven or emerging technologies in the water industry. In general, water workforces are not trained in digital technology solutions. This type of training is necessary to scale the adoption of digital technologies.

CIMCON’s Remote Terminal Units or RTU’s and SCANET Software systems has helped cities and municipalities efficiently deliver water and wastewater treatment for over 30 + years. With CIMCON’s vast experience in the water sector, these training and staffing issues are resolved. Instead of having to re-train the workforce in new technologies, CIMCON guides the water departments by taking care of the IoT Part in managing their assets in a better, more efficient manner.

Uttarakhand, a northern states in India is known for its beautiful natural environment of the Himalayas and is also referred to as “Devbhumi” or the land of Gods. The government of Uttarakhand had given a contract to the Uttarakhand Peyjal Nigam to provide drinking water to 40,000 villages in the Uttarakhand district which are spread far and wide across the mountains and difficult terrain. The mission was to provide proper drinking water to one crore citizens.

Being a hilly area, pumping stations are deployed for proper generation of water. But there were quite a few challenges in the pumping stations. In some extreme weather conditions, the pumping operators were not able to reach the pumping stations. Also, the operators used to handle the pumping stations manually, which led to loss of time and water not being pumped at regular intervals. All these challenges followed by manual intervention led to operators not following whether the overhead tanks were full or not, which led towater mismanagement.

Due to all these issues, Peyjal Nigam implemented CIMCON’s wireless remote monitoring solution to tackle the challenges. The remote terminal units along with CIMCON’s SCADA Systems were all connected with the central monitoring systems of the Peyjal Nigam and through GSM technology the operators of the Peyjal Nigam were notified about water issues through messages. Through CIMCON’s remote monitoring solutions, the flow, the level and the pressure of the water pumps can be measured effectively and reduced manual intervention with time.

Post implementing the solutions, Peyjal Nigam not only was able to manage the pumps effectively, but improved the efficiency of the pumps and reduced downtimes with proper interventions leading to improved productivity. CIMCON’s Remote Terminal Units and SCADA systems not only helped the water system to be managed automatically but alerts were generated earlier so that the field workers can go there and rectify the issues if needed. This has helped Peyjal Nigam in saving water and energy consumption by 60 percent and improving productivity by 40 percent.

The water department has made great strides in the uptake of digital technology. However, there is still plenty of room for improvement. Since technology has evolved, it is possible to take a great leap forward to achieve true digital transformation with minimal investment. Water departments need to start with a clear strategic plan to create a full digital ecosystem. This can start by dividing the water network into discrete zones and identifying what is needed to address the specific challenges in each. Effectively, it is best to start small by adding to existing technology. CIMCON can do this through connecting to a variety of existing water instruments without having to invest in new, expensive systems. Our product uses wired and wireless networks to communicate with water assets distributed over a large geographical area throughout a city. Then, it communicates this data back into the cloud using available network.

So, is digitalisation hard to implement? With CIMCON’s experience in the water industry and its wide range of solutions from hardware, software, SCADA and the latest predictive maintenance solutions with AI and ML technologies, digitalisation has never been easier to implement.

We are proud to announce that 𝐇𝐨𝐧’𝐛𝐥𝐞 𝐂𝐡𝐢𝐞𝐟 𝐌𝐢𝐧𝐢𝐬𝐭𝐞𝐫 𝐒𝐡𝐫𝐢. 𝐉𝐚𝐢𝐫𝐚𝐦 𝐓𝐡𝐚𝐤𝐮𝐫, 𝐆𝐨𝐯𝐞𝐫𝐧𝐦𝐞𝐧𝐭 𝐨𝐟 𝐇𝐢𝐦𝐚𝐜𝐡𝐚𝐥 𝐏𝐫𝐚𝐝𝐞𝐬𝐡, inaugurated the ‘𝐋𝐢𝐟𝐭 𝐖𝐚𝐭𝐞𝐫 𝐒𝐮𝐩𝐩𝐥𝐲 𝐒𝐜𝐡𝐞𝐦𝐞’ on Oct 9, 2022, for the village panchayat No. 19 of Seraj and Balichowki Block Tehsil, Thunag District, Mandi (Himachal Pradesh). The Chief Minister operated the pump using a singular command via our revolutionizing 𝐖𝐄𝐁𝐒𝐂𝐀𝐍𝐄𝐓 𝐬𝐨𝐟𝐭𝐰𝐚𝐫𝐞.

CIMCON Software India Pvt Ltd. is thankful to the Chief Minister for inaugurating one of our projects again. We would also like to thank the 𝐇𝐨𝐧’𝐛𝐥𝐞 𝐈𝐫𝐫𝐢𝐠𝐚𝐭𝐢𝐨𝐧 & 𝐏𝐮𝐛𝐥𝐢𝐜 𝐇𝐞𝐚𝐥𝐭𝐡 𝐌𝐢𝐧𝐢𝐬𝐭𝐞𝐫, 𝐒𝐡𝐫𝐢 𝐌𝐚𝐡𝐞𝐧𝐝𝐞𝐫 𝐒𝐢𝐧𝐠𝐡 𝐓𝐡𝐚𝐤𝐮𝐫, and the top authorities of the department for their presence, constant support, and guidance at our event.